CRADLE TO CRADLE® AT WÜRTH

A tree becomes a tree. Nature “operates” in a closed loop. Human beings make use of Earth’s warehouse. We mine, we produce, we throw away materials. At some point, Earth’s warehouse will be emptied. Unless we succeed in preserving the materials mined.

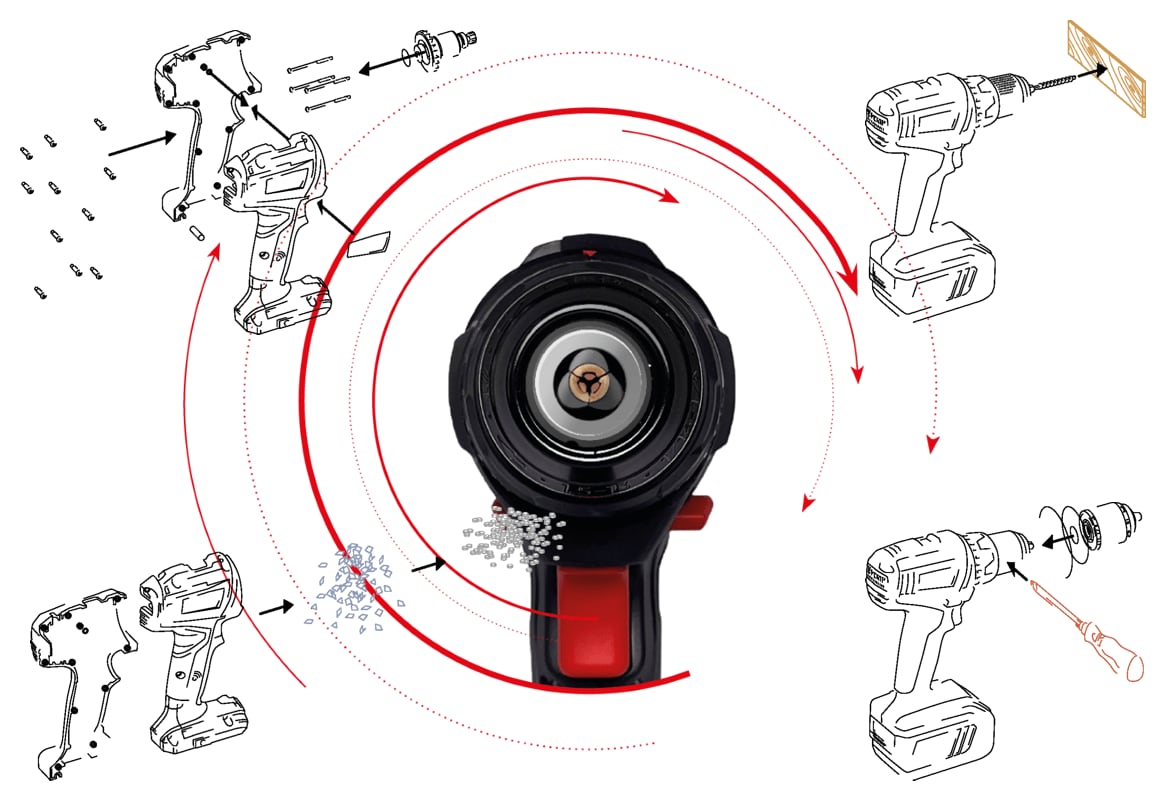

The purpose of the Cradle to Cradle® design concept is to create products that can be reused in recurring product cycles. The products are developed in such a way that as many of the materials used as possible can be recovered. This requires for product design and production to adopt a new mindset paving the way for a long and successful use phase as well as for easy repair and reuse of products. Once the products have reached the end of their useful life, they find their way back and are broken down into their constituent materials, which are then returned to nature and biodegraded or recycled. Materials circulate in recurring material cycles, with waste being consistently avoided.

Würth has been able to further develop some of its products and packaging, thus obtaining certification according to the Cradle to Cradle Certified® standard. These products include the VARIFIX® quick-mounting system , the packaging of our machining tools made from post-consumer recycled material as well as the ORSY® system rack. Drawing on these experience, we have taken up the challenge of addressing our M-CUBE power tools, one of our most complex product groups, and developing them further in accordance with the Cradle to Cradle Certified® standard.

Europe's largest award for ecological and social excellence. It honors companies that take on a pioneering role through visionary projects and initiatives.

Our M-CUBE power tools are pioneers in the circular economy. Developed for comprehensive material recovery, the cordless drill drivers ABS 18 Compact and ABS 18 Subcompact are the world’s first Cradle to Cradle certified® power tools.

Photo Credit: Frank Fendler

Our MASTERSERVICE has been extending the life cycle of our power tools since 1997. Whether repair, reuse or recycling - we bring sustainability to life.

Sustainability made measurable: With precise data on the environmental performance of M-CUBE power tools, we enable customers to meet the requirements of future-oriented projects.

Cradle to Cradle Certified®: M-CUBE power tools

1. Product design and production

In a joint effort, product management, research & development, and corporate sustainability management analysed, evaluated and further developed the cordless drill drivers ABS 18 Compact and ABS 18 Subcompact, the 18V M-CUBE rechargeable batteries as well as our ORSY®System cases based on the five Cradle to Cradle Certified® criteria.

- Material health

- Product circularity

- Clean air and climate protection

- Water and soil stewardship

- Social fairness

Around 80 percent of the environmental impact of a product is determined during the design phase. By using environmentally safe and recyclable materials, we create the basis for these materials to be reused for as long as possible even after the end of the product’s useful life and negative social and environmental impacts to be avoided. The production process of the M-CUBE power tools and the ORSY®System case was also analysed in detail, showing that Würth focuses not only on the use of energy and water but also on creating a positive work environment.

In parallel to the product, the ordering and packaging process was optimised as well. Having changed over to kitting, Würth revised both the product packaging and the shipping box. The product packaging was changed from outer packaging to paper banderoles. The shipping boxes were standardised in size and now go without four-colour prints, which has a positive effect on their recyclability. The new design allows for ergonomic and easier packing of the products. In addition, the optimised boxes ensure safer transport to the customer. The case insert material was changed from polstyrene to recycled ABS, supplied by a Germany-based company.

2. Use phase

Our customers can choose whether they want to buy our power tools or make use of our ORSY® fleet offering. The advantage of ORSY® fleet is that, in the event of a defect, our customers will receive rental tools free of charge for the duration of the repair and thus do not have to buy their own substitute tools. Our customers can also temporarily expand their fleet to cover peaks in demand. This allows our customers to only lease the power tools they regularly need. Regardless of the business model, the advantage of our M-CUBE battery system is that they are compatible with all M-CUBE power tools in the same voltage class. This way, the batteries can be put to their best possible use regardless of the power tool, which means that fewer batteries are needed.

3. Repair and reuse

Since 1997, WÜRTH MASTERSERVICE has been repairing, servicing and inspecting our customers’ power tool fleets. Meanwhile, WÜRTH MASTERSERVICE employs more than 120 people, including around 60 service technicians, who contribute to keeping our power tools in use for as long as possible. In addition to storing MASTER power tools, our ORSY®System cases can also be used for other purposes. ORSY®System cases are not only suitable for storing power tools, they also offer an optimum storage option for many other products and thus a wide range of applications thanks to their modular design. They can be used to store small parts, power tools and other tools together with consumables. Since the system inserts, system boxes and dividers are sold separately, our customers can always adapt their system cases to their needs, thus always being able to put their cases to new use.

4. Return and end of life

A well-thought-out product design is particularly advantageous if the products can be fed back to the respective material flows at the end of their useful life, allowing the constituent materials to be recovered. Therefore, it is important to us to offer our customers the opportunity to return their tools. For examples, our customer can send in defective power tools through our shops. If repairs are no longer possible, we have the end-of-life tools recycled by one of our qualified recycling partners. They ensure that the constituent materials are recovered. If ORSY® fleet power tools are returned after the end of the contract term, we will also check their functionality. Power tools that still function properly are given a second life in the rental and substitute tool pool, in the employee shop or as a donation for social projects. In school projects under the motto “make one out of three”, students were also able to give a second life to some defective power tools, gaining exciting practical experience on how to operate and repair power tools.

Our cordless drill/drivers are the first power tools of their kind that are Cradle to Cradle Certified®. This approach does not only set a new benchmark for Würth. However, this benchmark is just the beginning. We want to build on this foundation and continuously improve the recyclability of our power tools. Just like certification, higher performance levels for power tools of this type have not been achieved so far. In addition, product standards will be adjusted and requirements stepped up. For us, this is an incentive for research and development as well as for the upcoming recertification. The first steps towards a circular economy have been taken—and we want to go much further!

FAQ

Cradle to Cradle® describes the circulation of materials in closed, potentially infinite cycles. The concept aims to design products in such a way that their materials can be kept in sustainable material cycles.

The certificate assesses the extent to which products comply with the design concept. They are assessed in five ecological and social categories:

- Material health

- Product circularity

- Clean air and climate protection

- Water and soil stewardship

- Social fairness

For each category, there are five certification levels (Basic, Bronze, Silver, Gold, and Platinum) a product can achieve. At the same time, the lowest certification level across all of the categories determines the overall certification.

The different certification levels give incentive for the further development of the product. In addition, the standards are continuously adapted and the certification must be renewed on a regular basis every two years.

Various criteria have been defined within the categories. In addition, there is a list of excluded materials (potentially hazardous materials).

Looking at the entire life cycle requires transparency along the supply chain. This constitutes a challenge on a macroeconomic level. Coordination and cooperation within a circular supply chain are indispensable. We want to help shape an ecosystem as a central and strong partner.

Valuable resources will be preserved in the long run. This allows for fair cooperation across generations, strengthens wealth and protects the environment. We want to combine this new standard with the principle of growth, which is deeply ingrained in Würth’s DNA.

Material health is in the focus, harmful materials are excluded, increasingly critically reviewed and replaced by sustainable alternatives.

The energy intensity in production and supply chains is decreasing, renewable energies are preferred. The preservation of raw materials is often much more efficient than the mining of new raw materials, which is usually very energy-intensive.

The focus on social standards in production and the supply chain strengthens the principle of community. We consider this approach a driver of fair cooperation and source of innovative power.

In our current economy, processes are often linear: We take materials from Earth, produce products from them, and eventually throw them away as waste. In a circular economy, we do not produce waste in the first place.

The circular economy is based on three principles driven by product design:

- Elimination of waste and environmental contamination

- Circulation of products and materials (in consistent or higher quality)

- Regeneration of nature

The circular economy is to preserve valuable raw materials in the long term. This makes it a resilient and sustainable system across generations that is equally beneficial for businesses, people and the environment. At the same time, the cooperative strength of this economic model is the driving force behind social standards along the supply chain.

Adolf Würth GmbH & Co. KG collects and processes the personal data specified in the form in order to process the desired request for you. Please note the marked obligatory fields in the form. The legal basis for the processing of mandatory data is Article 6 para. 1 lit. b DSGVO, implementation of a pre-contractual measure. The processing of your voluntarily provided data is carried out based on Art. 6 para. 1 lit. f DSGVO. Thereafter, processing is permitted for the protection of our legitimate interests. Our legitimate interest is to be in contact with you, our customers, to improve our quality of advice and to be able to contact you more easily in case of possible queries. The collected data will be stored by us only as long as necessary for processing your inquiry as well as for getting in contact with you. After that, they will be deleted.

Additional data protection information, in particular regarding your rights of information, correction, deletion, limitation of processing, objection and complaint, can be found in our privacy policy.